MOGUL METALLIZING GMBH covers a wide range of equipment used in thermal spraying. On the base of decades of experience paired with ongoing innovation we manufacture installations which are easy to operate and long-lasting.

Besides the below mentioned standard equipment we offer special equipment made to customer requirements.

Powder-Fuse-Welding MOGUL XS 7 – Powder-Fuse-welding is a process where a so called self-fluxing powder (mainly Ni-base powders are used) is welded on a work-piece using an acetylene-oxygen flame.

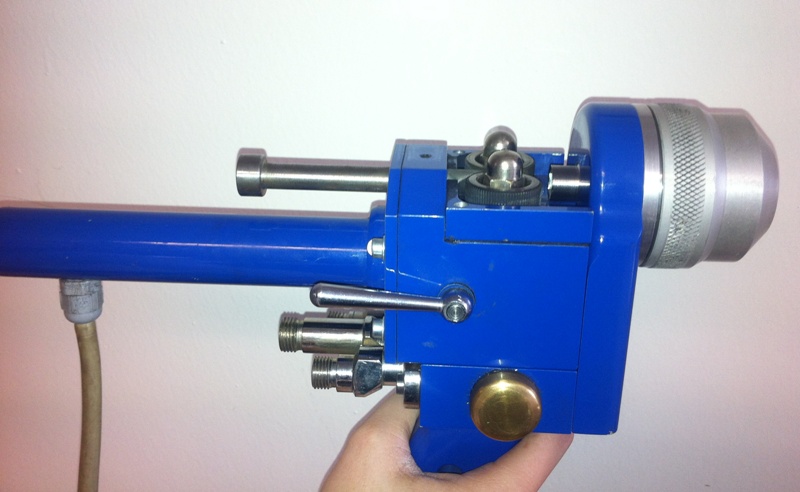

Wire-Flame-Spraying MOGUL RMTS Flame-Spraying is a process where a consumable in wire-form (also cords and rods can be sprayed) is molten in an acetylene (sometimes also propane) oxygen flame. The resulting particles are propelled to the substrate (which stays relatively cool) using compressed air (sometimes also a protective gas).

Rod-Flame-Spraying MOGUL RMTS. Rod-Flame-Spraying is a similar process as wire-flame-spraying. The difference is that the consumable is a rod. The advantage is that only molten particles are sprayed on the substrate which results in high quality. It is mainly used with oxid-ceramic rods.

Powder-Flame-Spraying MOGUL UP 1. Powder-Flame-Spraying is similar as wire-flame-spraying. The difference is that the consumable is a powder. This equipment is less expensive and for universal use.

Arc-Spraying MOGUL ARC NGI 500 M Pulse. Arc-Spraying is a process where two wires are brought to a short circuit. The wires melt and the molten particles are sprayed on the substrate (which remains relatively cool) using compressed air (sometimes also a protective gas). Usually the most economic process to produce coatings.

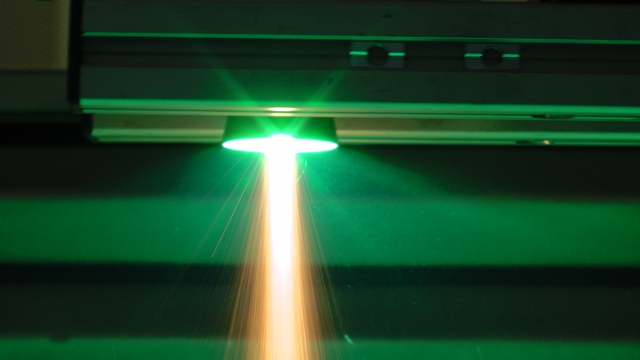

High-Velocity-Flame-Spraying (HVOF). Compared to powder-flame-spraying much higher gas pressures (fuel-gas ethylene or propane) are used resulting in very high particle speed and therefore creating denser coatings with higher bonding.

Plasma-spraying MOGUL IPP-TS Series. For plasma-spraying Mogul uses state-of-the–art inverter power supplies which are very economical in energy consumption. Plasma-Spraying is a process where a protective gas (mainly argon) is ionised using electrical energy. In this plasma-arc (which is not transferred to the work-piece) a powder is molten and sprayed on to the work-piece.